The Secret Behind Sawdust Charcoal

Recent Posts

Table of Contents

Introduction

Sawdust charcoal is a new, eco-friendly grilling solution. It is popular with BBQ fans. This eco-friendly option turns wood waste into premium fuel. It offers great heat retention and a steady burn. As demand for quality grilling charcoal rises, Indonesian sawdust briquettes are now becoming more popular. They are high-quality and eco-friendly.

The quest for sustainable grilling has spurred amazing innovations in charcoal production. Sawdust charcoal is at the forefront of this trend. It turns wood industry waste into premium BBQ fuel. This eco-friendly option has great heat retention and a steady burn. It is a game changer for both pro chefs and home grillers.

As demand for sustainable BBQ options grows, Indonesian charcoal is popular, especially briquettes. These high-quality briquettes will enhance your grilling and your BBQ. They are eco-friendly, too. There is a growing interest in how the makers of this incredible product create it. This reflects a shift to using the best, most sustainable charcoal options.

Key benefits of sawdust charcoal include:

Minimal environmental impact

Consistent heat distribution

Long-burning duration

Reduced smoke emissions

Superior flavor enhancement

King Briquettes Charcoal has been a leader in creating high-quality sawdust charcoal products. Their dedication to sustainability and excellence has set new industry benchmarks. They provide BBQ lovers with a green option that performs well.

Making top-notch charcoal from sawdust requires precise engineering and great care. This guide will walk you through each stage of this journey. It will show how waste material transforms into an essential grilling item.

What is Sawdust Charcoal?

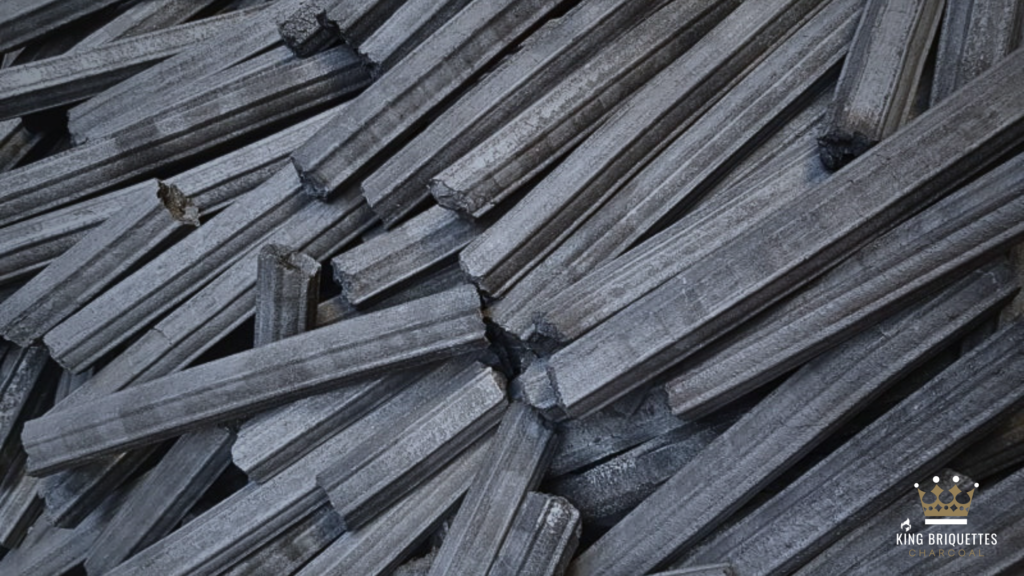

Sawdust charcoal is an eco-friendly fuel made from compressed sawdust waste materials. It is created through a process called carbonization, which involves heating the sawdust in the absence of oxygen to convert it into charcoal. This innovative product turns wood industry byproducts into high-quality cooking fuel.

Key Features:

- Dense and uniform structure

- Consistent heat output

- Low ash content

- Minimal smoke production

- Longer burning time

The benefits of sawdust charcoal make it an excellent choice for BBQ and grilling enthusiasts. Its carefully engineered density allows for superior heat retention, while its uniform shape ensures consistent cooking temperatures. The controlled manufacturing process results in a clean-burning fuel that imparts a subtle, natural smoky flavor to grilled foods without overpowering them.

Environmental Benefits:

- Utilizes waste materials from wood processing

- Reduces pressure on forest resources

- 60% lower carbon emissions during production

- No tree cutting required

- Supports circular economy principles

Indonesian sawdust charcoal producers like King Briquettes lead the industry in sustainable practices. By converting wood waste into premium cooking fuel, they demonstrate how innovative thinking can create superior products while protecting natural resources. The controlled manufacturing environment ensures each batch meets strict quality standards, delivering reliable performance for both professional chefs and home grillers.

The Process of Making Sawdust Charcoal

The transformation of sawdust into premium charcoal involves a meticulous process that begins with careful collection and preparation. At King Briquettes Charcoal, we’ve mastered each step to create superior BBQ and grilling fuel.

1. Sawdust Collection

The journey starts with sourcing high-quality sawdust from specific hardwood species.

- Premium Hardwoods:

The types of wood for sawdust briquette charcoal are various Indonesian tropical hardwoods. They come from natural forests. Manufacturers use them to make furniture, decking, flooring, pallets, and plywood.

The types of wood that are usually the main raw materials are:

- Merbau

- Ulin

- Bengkirai

- Keruing

- Meranti

- Mahogany

- Borneo Durian

- Sonokeling

- Trembesi

- Kaliandra

- And other hardwood species.

The types of wood that are usually used as raw materials for the mixture are:

- Pine

- Albasia

- Acacia

- Sungkai

- Jackfruit

- Mango

- And other medium/softwood species.

We can accept the following types or forms of wood powder:

- Sawmill

- Molding

- Sending

- Small Chip

A press machine will carbonize it. This will produce a high-quality sawdust briquette charcoal. Both domestic and international markets will accept it.

Each charcoal has exceptional burning properties and minimal ash content. The sawdust collection process focuses on the following:

- Quality Control Measures: Consistent particle size. Moisture content monitored. Contaminants removed. Species verified.

Our sustainable sourcing practices include:

- Partnerships with certified wood-processing facilities

- Direct collection from furniture manufacturers.

- Collaboration with sustainable forestry operations

The environmental impact of sawdust collection extends beyond simple waste reduction.

- Environmental Benefits: Reduces landfill waste, prevents burning of wood waste, supports a circular economy, and minimizes pressure on forests.

Each batch undergoes rigorous testing to ensure:

- Material Standards:

- Optimal moisture levels.

- Proper particle size distribution.

- No chemical treatments.

- Consistent wood species.

This quality control at the collection stage ensures premium sawdust charcoal. The collected material undergoes more processing. This is to make it ideal for BBQ and grilling.

2. Crushing Wood Waste

The crushing phase transforms raw wood waste into precisely sized particles – a critical step for creating high-quality sawdust charcoal. This process employs specialized equipment:

Primary Crushing Equipment:

- Hammer Mills: Industrial-grade machines that break down larger wood pieces through high-speed impact

- Wood Chippers: Ideal for processing bulkier waste materials into manageable sizes

- Industrial Grinders: Creates uniform particle distribution for consistent burning

Size Requirements:

- Optimal particle size: 2-5mm

- Uniform consistency ensures:

- Even carbonization

- Consistent burning temperature

- Superior briquette formation

Quality Control Measures:

- Screening systems separate oversized particles

- Magnetic separators remove metal contaminants

- Moisture monitoring throughout the crushing process

At King Briquettes Charcoal, advanced crushing technology maintains precise particle size control. This attention to detail during the crushing phase directly influences the final product’s burning efficiency and heat output. The carefully crushed sawdust creates the foundation for premium-grade charcoal briquettes that deliver superior grilling performance.

3. Drying the Sawdust

The drying phase is a crucial step in sawdust charcoal production. Raw sawdust usually has 30-50% moisture. It needs to be 8-12% for optimal briquetting and carbonization.

Air Drying Method:

- Natural sunlight exposure for 2 to 3 days.

- Spread sawdust in thin layers on concrete platforms.

- Regular turning for uniform drying

- Cost-effective, but weather-dependent

Industrial Drying Systems:

- Rotary drum dryers

- Flash dryers

- Belt dryers

- Temperature control between 100-120°C

- Processing time: 15–30 minutes

Impact on Product Quality:

- Proper moisture levels ensure:

- Enhanced binding properties

- Improved compressive strength

- Higher calorific value

- Reduced smoke during use.

- Better carbonization results.

King Briquettes Charcoal uses advanced drying technology. It maintains precise moisture control with automated monitoring systems. This care in drying produces high-quality sawdust charcoal briquettes. They burn better than others.

The dried sawdust undergoes thorough testing to ensure optimal moisture. Then, it moves to the briquetting phase. This careful method ensures top BBQ and grilling. Each batch meets high-quality standards.

4. Briquetting the Sawdust

The briquetting process transforms loose sawdust into dense, compact fuel sources through advanced compression techniques. Modern briquetting machines apply pressures ranging from 1,000 to 1,500 kg/cm², creating uniform-sized briquettes with exceptional burning properties.

Key Components of Briquetting:

- Compression Chamber: Specialized equipment shapes sawdust into cylindrical or hexagonal forms

- Pressure Control: Precise pressure regulation ensures consistent density

The high-pressure compression creates briquettes with superior characteristics:

- Increased density (1.1-1.3 g/cm³)

- Extended burning time (30-40% longer than traditional charcoal)

- Reduced ash content (less than 5%)

- Enhanced heat output (6,500-7,500 kcal/kg)

Manual briquetting methods, while less common in commercial production, remain viable for small-scale operations. Hand-operated presses can produce briquettes at 100-200 kg/cm² pressure, suitable for local market distribution.

Quality control during briquetting directly impacts the final product’s performance. Automated systems monitor pressure levels, moisture content, and briquette size to maintain consistent production standards. This attention to detail ensures each briquette meets strict specifications for optimal grilling performance.

5. Carbonizing the Briquettes

Here we explain the Production Process in the Sawdust Briquette Charcoal Factory.

The production process at the Sawdust Briquette Charcoal Plant differs significantly from the Coconut Briquette Charcoal Factory.

The carbonization phase transforms raw sawdust briquettes into high-quality charcoal through controlled heating in an oxygen-limited environment. This critical process removes volatile compounds while preserving the carbon structure.

The process begins with mixing various types of wood powder raw materials with carefully formulated percentage ratios. This initial mixing is performed manually with the assistance of a wheel loader.

Following the manual mixing, the blended sawdust raw material is transferred to the raw material sawdust tank and conveyed to the mixer machine. This secondary mixing ensures a more perfect blend of various wood types, establishing 30% of the final product’s quality determination.

From the mixer, the perfectly blended sawdust flows through ducting to the rotary dryer machine. The drying process is enhanced by a cyclone jet blower, ensuring optimal dryness before entering the high-pressure extruder briquette machine.

The high-pressure extruder briquetting machine process is crucial, accounting for another 30% of the final sawdust briquette charcoal quality.

After pressing, the formed briquettes are transported via conveyor to the briquette tank and then distributed to the carbonization stove kiln oven.

The carbonization process in the furnace is responsible for 40% of the final product quality. Ideal carbonization requires a 21-day cycle:

- 14 days of burning

- 6 days of cooling

- 1 day for unloading

- Upon completion of the 21-day cycle, the sawdust briquette charcoal is ready for packing and sorting based on grade classification before distribution.

King Briquettes Charcoal utilizes state-of-the-art retort systems with precise digital controls to maintain ideal temperatures throughout the process. This technology ensures each batch meets strict quality standards for:

- Fixed carbon content >75%

- Moisture content <5%

- Ash content <5%

- Volatile matter <20%

The carefully controlled carbonization process creates charcoal briquettes with superior heat retention and minimal smoke production – essential qualities for perfect BBQ results.

6. Final Product Characteristics

Premium sawdust charcoal exhibits distinct qualities that set it apart from traditional charcoal options:

Density and Structure

- Compressed at high pressure creating a solid, uniform structure

- Enhanced thermal efficiency due to concentrated mass

- Longer burning time compared to conventional charcoal

Moisture and Volatile Content

- Moisture content below 5% ensures consistent performance

- Minimal volatile matter reduces smoke production

- Clean burning characteristics ideal for indoor and outdoor use

Performance Metrics

- Heat output: 7,500 – 8,500 kcal/kg

- Ash content: Less than 5%

- Fixed carbon: 85-90%

- Moisture Content: Less than 3%

Versatile Applications

- Commercial Uses Restaurant grilling

- Industrial heating systems

- Metal smelting operations

- Chemical processing

The high-density nature of sawdust charcoal briquettes makes them particularly valuable for applications requiring sustained heat output. Their uniform size and shape allow for precise temperature control, while the minimal ash production reduces maintenance requirements. These characteristics make sawdust charcoal briquettes an excellent choice for both professional and home cooking environments.

Comparative Analysis: Sawdust Charcoal vs Other Types

Let’s examine how sawdust charcoal briquettes stack up against other popular charcoal varieties:

1. Lumpwood Charcoal

Pros: Natural wood flavor, quick lighting

Cons: Irregular shapes, burns faster, higher cost

2. Indonesian Binchotan

Pros: Extremely high heat, minimal smoke

Cons: Expensive, requires special lighting techniques

3. Sawdust Briquettes

Pros:

- Consistent size and shape.

- Steady heat distribution

- Cost-effective

- Environmentally sustainable

- Longer burning time

Cons: Requires proper storage to avoid moisture absorption.

Sawdust briquettes have a uniform shape and size. They create predictable cooking conditions. This makes them ideal for both pro chefs and home grillers. Their clean burn and eco-friendly production make them a top choice for modern enthusiasts.

Best Practices for Using Sawdust Charcoal in BBQ and Grilling

Maximizing your BBQ experience with sawdust charcoal starts with selecting the right equipment. Ceramic and high-quality stainless steel grills provide optimal heat retention and temperature control for sawdust charcoal briquettes.

Essential tips for perfect grilling:

- Pre-heat your grill for 15-20 minutes before cooking

- Arrange briquettes in a pyramid shape for efficient lighting

- Maintain proper airflow by adjusting vents appropriately

- Add fresh briquettes when needed to maintain a consistent temperature

Temperature control guide:

Heat Level Temperature (°F) Number of Briquettes Low | 225-250 | 12-15 |

Medium | 325-350 | 20-25 |

High | 450-500 | 30-35 |

For the ultimate grilling experience, King Briquettes Charcoal is the premium choice for BBQ enthusiasts. Their Indonesian sawdust charcoal briquettes deliver consistent heat, minimal ash, and a clean burn that enhances food flavor. Made from sustainable materials and crafted with precision, King Briquettes Charcoal represents the perfect blend of environmental responsibility and grilling excellence.

1. Natural Fertilizer

Coconut charcoal ash is rich in potassium and can improve soil quality. Mixing it into garden beds or potted plants enriches the soil, promoting healthy plant growth.

2. Pest Control

The fine texture of ash can deter pests like slugs and snails when sprinkled around garden edges, providing a natural barrier without harsh chemicals.

Choosing sustainable charcoals such as coconut not only supports eco-friendly grilling but also aligns with a broader commitment to reducing one’s ecological footprint.

Consider these practices during outdoor cooking activities:

- Use reusable grill mats or biodegradable paper products.

- Opt for locally sourced ingredients to minimize transportation emissions.

- Encourage friends and family to adopt sustainable grilling habits, spreading awareness about the benefits of eco-friendly alternatives.

Incorporating these actions fosters a communal effort toward environmental stewardship while enjoying delicious meals outdoors.

Conclusion

Sawdust charcoal has changed grilling. It is a sustainable, efficient, high-performance alternative to traditional charcoal. Its unique process, consistent heat, and low ash make it ideal for both amateur grillers and professional chefs. Sawdust charcoal has great burning traits and eco-friendly benefits. So, it is a smart choice for modern BBQ fans. The strict process makes a product that works well and is eco-friendly. Sawdust charcoal can keep steady temperatures. It creates a perfect cooking environment. So, it is a reliable fuel for many grilling tasks. King briquettes charcoal stands out as the best choice for those seeking premium quality, consistent performance, and environmental sustainability in their grilling endeavors.

FAQs (Frequently Asked Questions)

What is sawdust charcoal?

Sawdust charcoal is a type of charcoal made from compressed sawdust. It offers unique benefits for BBQ and grilling, including a distinct flavor profile and excellent heat retention properties. Additionally, it has environmental advantages over traditional charcoal, such as reduced deforestation and lower carbon emissions during production.

How is sawdust charcoal produced?

The production of sawdust charcoal involves several key steps: collecting high-quality sawdust, crushing wood waste into uniform sizes, drying the sawdust to reduce moisture content, briquetting the sawdust into dense shapes, and finally carbonizing the briquettes in a controlled environment to remove volatile compounds and achieve optimal char quality.

What are the environmental benefits of using sawdust charcoal?

Sawdust charcoal is considered more sustainable compared to traditional charcoal options. Its production utilizes wood processing waste material, which helps minimize environmental impact by recycling resources. This process leads to reduced deforestation and lower carbon emissions associated with its manufacturing.

What distinguishes premium sawdust charcoal products?

Premium sawdust charcoal products are characterized by high density, low moisture content, and minimal volatile matter. These features contribute to a longer burn time and less ash production, making them ideal for applications beyond BBQ and grilling, such as industrial heating or activated carbon production.

How does sawdust charcoal compare to other types of charcoal?

When compared to other types of charcoal like lump charcoal or coconut shell charcoal, sawdust briquettes often provide better heat retention and a cleaner burn. However, each type has its own pros and cons depending on factors like flavor profile and burning characteristics.

What are the best practices for using sawdust charcoal in BBQ and grilling?

To maximize the benefits of sawdust charcoal for BBQ and grilling, it’s essential to choose the right grill type—ceramic or stainless steel grills work well with this fuel source. Additionally, proper lighting techniques and maintaining airflow can enhance performance during cooking.

Author: Admin | Date: 17 December 2024